INSTALLATION:

We recommend installing the floor professionally (we will help arrange it if ordered). With adequate skill, it is possible to handle the assembly yourself. The table below provides an overview of the options, the procedure itself can be found in the INSTALLATION section.

| Method of assembly |

quality |

costs |

complexity of installation |

| Glue down |

***** |

***** |

***** (for professional instalation) |

| Self-adhesive ELASTILON system |

**** |

**** |

** (easy instalation) |

| Caterpilar gluing |

*** |

*** |

*** (medium instalation) |

| Nailing |

** |

** |

** (simple, grate neccessary) |

| Gluing of tongue and groove |

* |

* |

* (very easy) |

INSTALLATION RECOMMENDATIONS:

- full-area gluing - elastic adhesives, high-quality PU penetration

- ELASTILON - STRONG version

- caterpillar gluing - elastic glues in "salami" packaging

- nailing – grate with the density of 300mm

- simple gluing of the joint - glue class D3

UNDERFLOOR HEATING:

The multi-layer construction of the floor meets the demanding requirements for underfloor heating in terms of density, thermal resistance, stability and is considered the best for this purpose.

High construction density:

Across the whole structure, there is only deciduous wood of similar density as oak, 700kg / m3. The tabular coefficient of thermal conductivity is 0.18W / m.K (this construction has a 50% higher density than conventional 3-layer floors).

Thanks to this, a favorable value of thermal resistance is achieved, which accelerates the onset of underfloor heating.

High stability (necessary for underfloor heating):

The multilayer construction of 8 layers rotated by 90 ° makes the parquet superstable, resistant to spatial and volume changes.

The professional tongue-and-groove joint also has an inseparable effect on the stability of the installation, which protects the floor from horizontal transmission even from small volume changes between the individual lamellae. To take advantage of this advantage, it is necessary to install the floor only by gluing to the substrate or to the ELASTILON self-adhesive system.

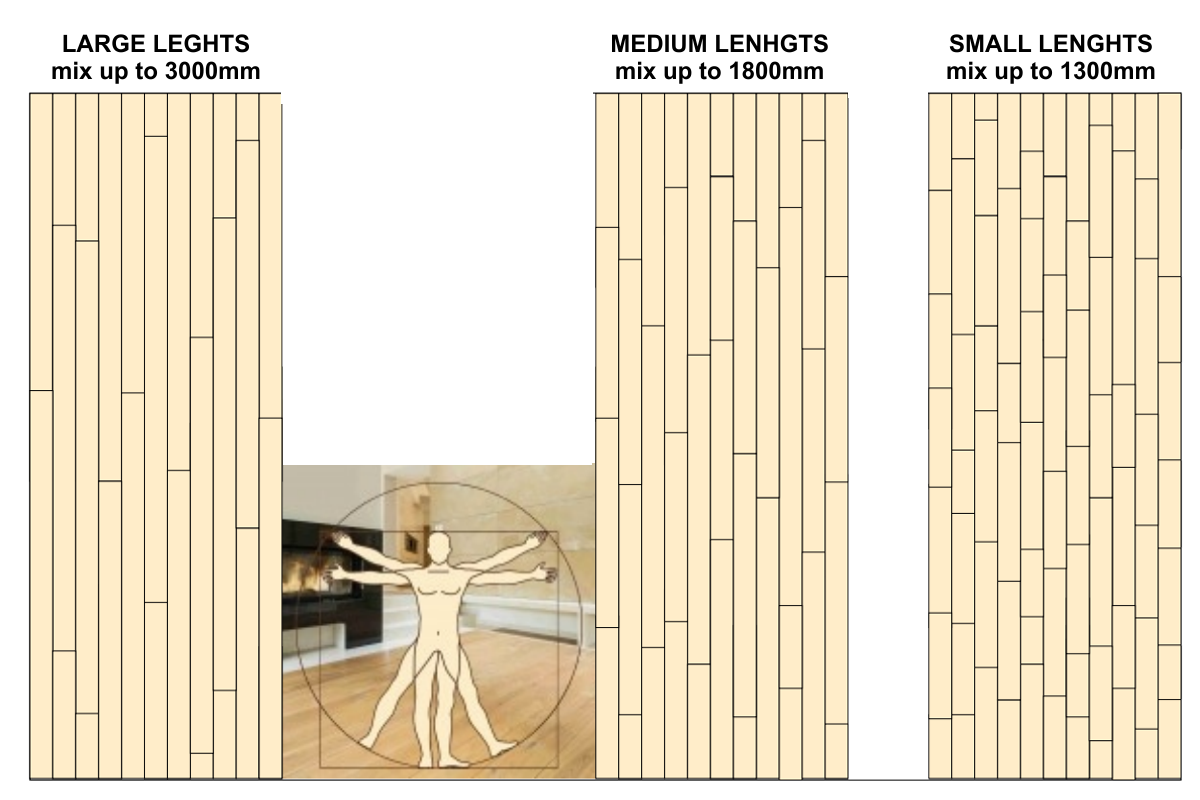

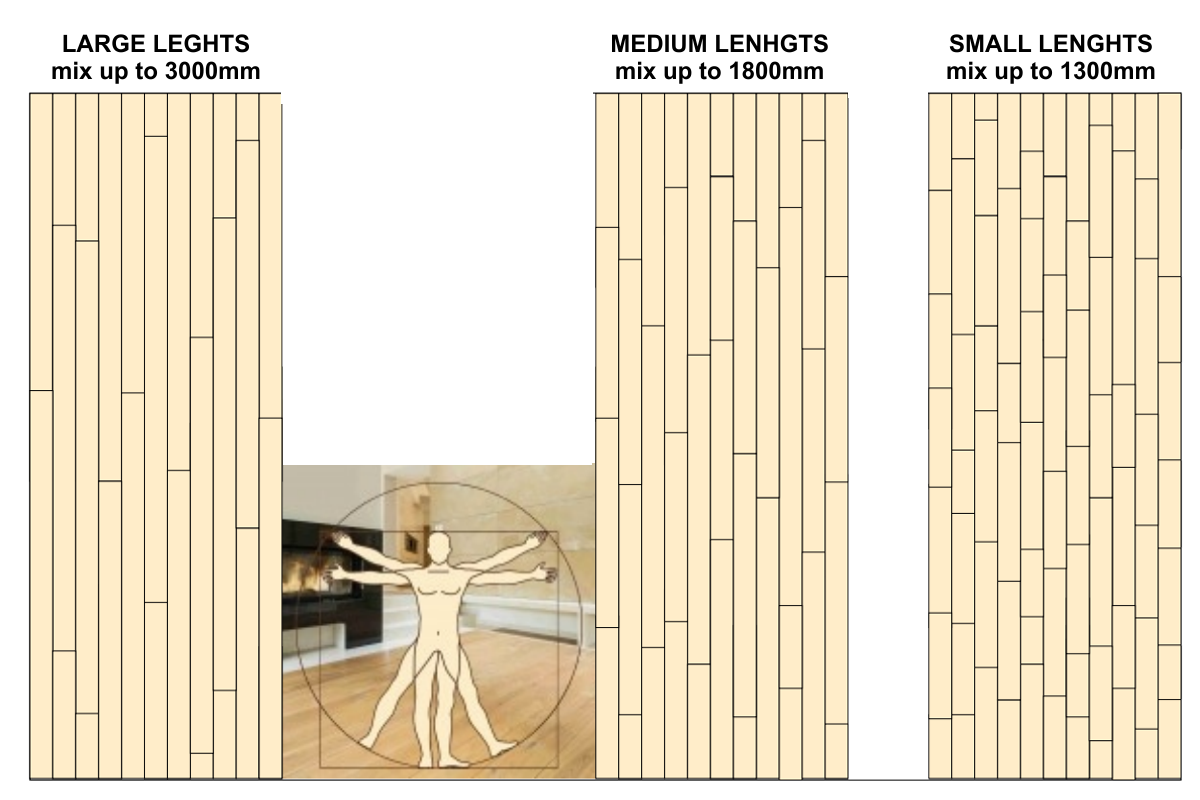

Comparison of laying different mix of floor lengths: